10 Best Corded Impact Wrenches 2025 in the United States

Winner

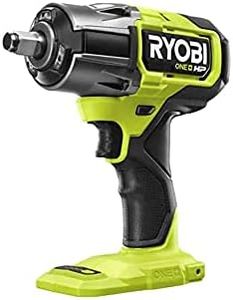

RYOBI - ONE+ HP 18V Brushless Cordless 4-Mode ½ in. Impact Wrench (Tool Only) - P262

The RYOBI ONE+ HP 18V Brushless Cordless 4-Mode ½ in. Impact Wrench is an appealing choice for users seeking portability and flexibility, thanks to its cordless design. Operating on an 18V battery, this wrench frees users from the limitations of cords, making it highly convenient for mobility. Its compact size and hex-shaped head enhance maneuverability, allowing it to fit snugly into tight spaces, which is especially useful for automotive or construction tasks.

Most important from

1267 reviews

DEWALT Impact Wrench, Square Drive, Heavy Duty, 1/2-Inch (DWMT70773L)

The DEWALT Impact Wrench (DWMT70773L) is a solid choice for those needing a reliable corded impact wrench. It boasts a powerful torque of 650 ft-lb, making it effective for loosening stubborn fasteners, which is a significant advantage for both professional mechanics and DIY enthusiasts. With a free speed of 7500 RPM at 90 PSI, it delivers speedy performance, allowing for efficient fastening tasks.

Most important from

1590 reviews

CRAFTSMAN Impact Wrench, 1/2 inch, 7.5 Amp, Corded (CMEF901)

The CRAFTSMAN Impact Wrench (CMEF901) is a corded, 1/2-inch wrench that delivers a solid 7.5 amps of power. It offers 450 ft.-lbs. of torque, which is impressive for quickly removing larger fasteners. The 2,700 impacts per minute (IPM) and 2,200 RPM with a variable speed trigger provide good control and efficiency during use. The hog ring anvil design makes socket changes quite easy, which can save time on the job.

Most important from

627 reviews

Top 10 Best Corded Impact Wrenches 2025 in the United States

Winner

9.9 score

RYOBI - ONE+ HP 18V Brushless Cordless 4-Mode ½ in. Impact Wrench (Tool Only) - P262

RYOBI - ONE+ HP 18V Brushless Cordless 4-Mode ½ in. Impact Wrench (Tool Only) - P262

Chosen by 1196 this week

DEWALT Impact Wrench, Square Drive, Heavy Duty, 1/2-Inch (DWMT70773L)

DEWALT Impact Wrench, Square Drive, Heavy Duty, 1/2-Inch (DWMT70773L)

CRAFTSMAN Impact Wrench, 1/2 inch, 7.5 Amp, Corded (CMEF901)

CRAFTSMAN Impact Wrench, 1/2 inch, 7.5 Amp, Corded (CMEF901)

PORTER-CABLE Impact Wrench, 450 lbs of Torque, 1/2 Inch Hog Ring, 7.5-Amp, Corded (PCE211)

PORTER-CABLE Impact Wrench, 450 lbs of Torque, 1/2 Inch Hog Ring, 7.5-Amp, Corded (PCE211)

Metabo HPT Impact Wrench, Corded, AC Brushless Motor, 3/4" Square Drive, Aluminum Housing Body (WR22SE)

Metabo HPT Impact Wrench, Corded, AC Brushless Motor, 3/4" Square Drive, Aluminum Housing Body (WR22SE)

MILWAUKEE'S Impact Wrench, 120VAC, 7.0 Amps, 1/2" (9070-20)

MILWAUKEE'S Impact Wrench, 120VAC, 7.0 Amps, 1/2" (9070-20)

Eastvolt 800W Electric Impact Wrench, Heavy Duty 7.5 Amp Corded Max Torque 450 Ft-lbs 3400 RPM, 1/2 Inch with Hog Ring Anvil

Eastvolt 800W Electric Impact Wrench, Heavy Duty 7.5 Amp Corded Max Torque 450 Ft-lbs 3400 RPM, 1/2 Inch with Hog Ring Anvil

BAUER 64120 1/2 Inch Heavy Duty Extreme Torque Impact Wrench with Rubber Nosepiece

BAUER 64120 1/2 Inch Heavy Duty Extreme Torque Impact Wrench with Rubber Nosepiece

Wild Edge Impact Wrench Kit, Heavy Duty 1/2 Inch Drive 7.5 Amp Corded Impact Gun, Max Torque 240 Ft-lbs & 2700 IPM, 4pcs Durable Sockets with Detent Anvil

Wild Edge Impact Wrench Kit, Heavy Duty 1/2 Inch Drive 7.5 Amp Corded Impact Gun, Max Torque 240 Ft-lbs & 2700 IPM, 4pcs Durable Sockets with Detent Anvil

8.0 score

WEN Two-Direction Corded Impact Wrench, 7.5-Amp with 1/2-Inch Hog Ring Anvil (48108)

WEN Two-Direction Corded Impact Wrench, 7.5-Amp with 1/2-Inch Hog Ring Anvil (48108)

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.